Material selection plays a fundamental role in the long-term success of any fabrication project. The choice between stainless steel, carbon steel, and aluminum involves careful consideration of multiple factors, including mechanical properties, corrosion resistance, cost efficiency, fabrication method, and end-use environment. The experts at Onhydro Tech specialize in guiding clients through this complex decision-making process, supported by advanced capabilities in welding, in-shop metal fabrication, mobile welding, engineering, and project management.

Stainless Steel: Corrosion Resistance and Strength

Stainless steel remains a preferred material for numerous fabrication projects due to its exceptional corrosion resistance, durability, and aesthetic appeal. Composed primarily of iron, chromium (at least 10.5%), and additional alloying elements such as nickel and molybdenum, stainless steel forms a passive protective layer that guards against corrosion even in harsh environments.

Applications that demand hygiene, such as food processing, pharmaceuticals, and healthcare, benefit greatly from stainless steel’s non-porous surface and ease of sterilization. In architectural and structural projects, its combination of strength and visual appeal offers longevity and reduced maintenance costs.

Welding stainless steel requires precise technique. Onhydro Tech employs TIG welding (GTAW), known for its high-quality and clean welds, particularly effective for thinner stainless components. For thicker sections, MIG welding (GMAW) offers speed and efficiency, while MMA welding (SMAW) is utilized in field conditions where portability is essential.

Carbon Steel: Versatility and Cost-Effectiveness

Carbon steel, composed primarily of iron and carbon, provides versatility at a relatively low cost, making it suitable for structural, automotive, and industrial equipment applications. Depending on the carbon content—ranging from low to high carbon—mechanical properties such as hardness, tensile strength, and ductility can be precisely adjusted to meet the demands of a specific project.

One of carbon steel’s primary challenges is its susceptibility to corrosion. Protective coatings such as paint, galvanization, or specialized finishes are often applied to prolong service life. Nonetheless, carbon steel’s strength-to-cost ratio continues to make it a highly sought-after material for heavy machinery, piping systems, and large-scale infrastructure.

MIG welding proves highly effective for carbon steel due to its speed and adaptability, while MMA welding offers additional flexibility in outdoor and less controlled environments. Onhydro Tech’s team is proficient in multiple welding processes, ensuring structural integrity and consistent results across various project conditions.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum distinguishes itself through its lightweight properties and natural resistance to corrosion. Its strength-to-weight ratio makes it ideal for applications where weight reduction is critical, such as aerospace, marine, transportation, and certain architectural structures.

Although aluminum is inherently corrosion-resistant, its lower melting point and higher thermal conductivity present unique challenges during welding. Onhydro Tech utilizes specialized TIG welding for aluminum, delivering precision and minimizing deformation. MIG welding is also employed when thicker aluminum components require rapid deposition rates and strong welds.

With careful process control and proper filler material selection, aluminum fabrications achieve long-lasting performance in environments where both strength and minimal weight are essential.

The Role of Fabrication Methods and Project Management

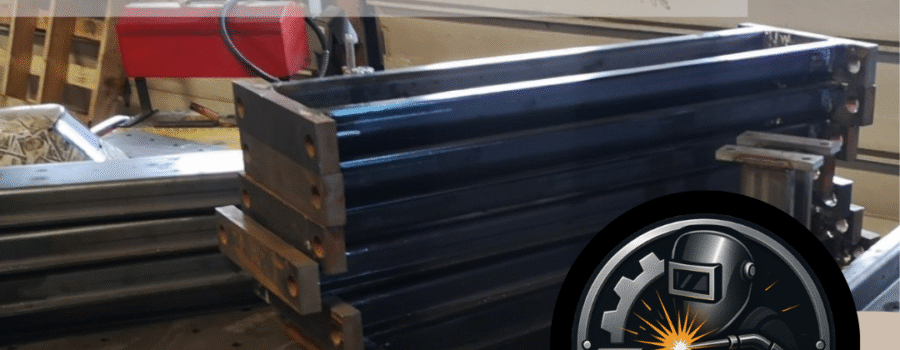

Beyond material selection, successful fabrication depends on a comprehensive approach that includes engineering, project management, and quality control. Onhydro Tech offers both in-shop metal fabrication and mobile welding services to meet diverse client needs across Cambridge, Kitchener, and Waterloo.

In-shop metal fabrication enables controlled environments, precise machining, and complex assemblies under strict quality standards. Mobile welding provides onsite solutions that minimize downtime and allow for rapid response to client requirements, supported by certified welders skilled in MIG, TIG, and MMA welding techniques.

Project management ensures timely completion, budget adherence, and strict compliance with Canadian standards and legal regulations. The combination of engineering expertise and hands-on fabrication capabilities allows Onhydro Tech to address complex fabrication challenges with confidence.

Fabrication is not merely about joining metals—it requires expert planning, technical precision, and in-depth understanding of materials. For tailored solutions and expert consultation on stainless steel, carbon steel, or aluminum fabrication, contact Onhydro Tech at 647-248-6682 or visit onhydrotech.ca. Experience fabrication excellence backed by full-service welding, advanced engineering, and reliable project management.